Among the most flexible and robust materials used in contemporary building, manufacturing, and many other industries is steel tubing. From structural frameworks to fluid transportation systems, it finds extensive usage in many different fields. This ultimate guide will discuss the advantages of steel tube, its several forms, and the several uses it finds in different sectors.

What is steel tubing?

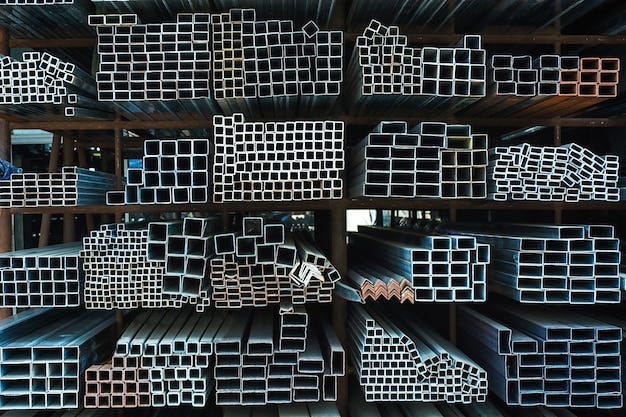

Steel tubing is the hollow cylindrical sections produced from steel. Different techniques include seamless extrusion, electric resistance welding, or welding are used in manufacture. Though they are made in many forms and sizes, round, square, and rectangular are the most often used forms in steel tubes. Mostly utilised for structural and mechanical needs, these tubes provide strength, resistance to wear, and longevity.

Different kinds of steel tubeing

There are several kinds of steel tube, each fit for a different use according on its qualities. These are the primary forms:

Perfectly crafted steel tube: Made without any seams or joints, this kind guarantees maximum strength and dependability. High-pressure systems such as hydraulic lines and industrial pipelines make seamless steel tubes rather popular.

Advantages of steel tube construction

1. Durability and Strength

Great strength and durability of steel tubing are among its main benefits. Steel is well known for resisting environmental elements, tension, and large volumes of pressure. For demanding sectors including construction, automotive, and manufacturing, steel tube provides dependable performance over time whether employed in structural applications or mechanical systems.

2. Resistive corrosion

Particularly when treated or coated in anti-corrosive compounds, steel tubing is quite rust and corrosion resistant. This makes it ideal for usage in outdoor or moisture-sensitive surroundings including plumbing systems, marine constructions, and outdoor railings. Particularly well-known for its great resistance to corrosion, stainless steel tubing is extensively utilised in sectors including food processing and pharmaceuticals that call for sanitary conditions.

3. Adaptability

Extreme adaptability of steel tubing makes it appropriate for many kinds of use. Simple projects like building fences and railings to more complicated uses in oil pipelines or aerospace components, steel tube can be tailored to fit certain project requirements. Its easy cutting, welding, and shaping makes it fit into any design or use.

4. Economical

Although steel tubing could be more expensive initially than other materials, over time its cost-effectiveness is determined by its lifetime and resilience to wear and tear. For projects requiring strength and longevity, steel tube makes a wise investment since it requires less maintenance and replacement, therefore lowering long-term costs.

5. Weightless

When compared to solid steel beams or bars, steel tubing is rather light even with its strength. For big-scale building or industrial projects, this simplifies transportation and installation, which is quite advantageous. Its small weight also facilitates uses such in cars or equipment that call for a mix of strength and mobility.

Typical uses for steel tubing

1. Building

A staple component of the building sector is steel tube. Building structural frameworks including columns, support beams, and scaffolding depends on it. Its stability and strength make it ideal for keeping structural integrity while sustaining large weights. Because of its durability and visual appeal, steel tube is also frequently used for fencing, guardrails, and handrails.

2. Aerospace and Automotive sectors

Building vehicle frames, exhaust systems, and fuel lines in the automotive and aerospace sectors depends critically on steel tubing. Steel tubing's strength and adaptability let builders build lightweight yet robust constructions able to resist high speeds and harsh temperatures. Particularly helpful for guaranteeing the lifetime of parts subjected to demanding conditions is the corrosion resistance of the tube.

3. Liquid Transportation and Plumbing

Particularly for moving water, gas, and other fluids, steel tubing finds great application in plumbing systems. Residential and commercial plumbing would benefit much from its resistance to corrosion and handling of high pressure. Particularly employed in sanitary water systems and medical gas lines, where dependability and hygiene are paramount, is stainless steel tubing.

4. Oil and Energy sectors

Steel tubing finds use in drilling rigs, pipelines, and refineries in the energy and oil sectors. Its capacity to manage high temperatures and pressures makes it perfect for securely moving natural gas and oil across great distances. Offshore platforms and other structures where durability and environmental factor resistance are crucial are another usage for steel tube.

5. Design and Furnace

Modern furniture design makes great use of steel tubing because of its elegant look and strength. Common goods include seats, tables, shelves, and even ornamental accents have it. Interior designers and architects often choose steel tube because of its modern style, simplicity of manufacture, and durability.

Last Thought

One amazing material with great range of uses is steel tubing. From allowing fluid movement in plumbing to adding structural integrity in building, steel tubing is absolutely essential in many different fields. For tasks calling for a dependable and long-lasting solution, its strength, durability, corrosion resistance, and adaptability rank highest.

Call Texas Iron & Metal if you want premium steel tubing for your next project. Our large range of steel tube choices guarantees that you will be able to locate the ideal material for your requirements. Get in touch right now for professional guidance and the best steel tube options for your company or building project.